BRYAN, Ohio– Allied Moulded Products, Inc. is excited to feature the release of their latest addition to the SLIDERBOX® family, the 2302-ABKSC, a 2-gang follow up to the innovative 1099-AB Adjustable Fiberglass Outlet Box. This game changing product is UL® listed and has a 2-hour wall fire rating, making it a safe and reliable choice for electrical installations.

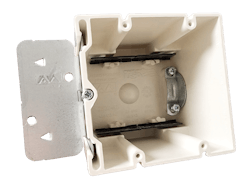

The newest addition to the SLIDERBOX® family, the 2302-ABKSC is revolutionizing the industry and the world of EV chargers as the only two gang adjustable outlet box made from Allied Moulded’s patented fiberglass material. With unmatched strength and durability, the 2302-ABKSC will not warp or hourglass like some plastic boxes, even in extreme heat. And with an industry-leading internal volume of 42.5 in3, this box has plenty of space for heavy duty wiring for large appliances such as ranges, dryers, and the increasingly popular EV chargers.

The 2302-ABKSC was also built with convenience in mind. It’s lightweight and easy to handle and includes both a steel clamp and Speed “K” KlampsTM to secure wiring for faster installation and a no-cost way of meeting National Electrical Code requirements. Because of the properties of Allied Moulded’s fiberglass material, when installed maintaining a 3” horizontal separation and following local building codes, the 2302-ABKSC does not require putty or sound pads to be added, saving contractors valuable time and money, not to mention the mess! Perhaps most notable about the 2302-ABKSC is its adjustable features. Contractors love the convenience of the single screw adjustment and the ability to adjust the box after drywall and other wall substrates have been installed. With the ability to travel a full 2”, this box has the highest adjustability range on the market, making it the perfect solution for varying thickness of drywall, plywood, backsplashes, stone, brick and more!

“Allied Moulded is always looking for opportunities to expand our product offerings in innovative ways,” said Dustin Morr, Product Manager. “The 2302-ABKSC is one of those products that can not only be used in the innovative EV charging market but can also be used by any home owner in kitchens or garages that may be fitted with all the new large devices and appliances that demand the market leading cubic volume of this product.”

Allied Moulded provides a complete line of wall and ceiling boxes for most electrical applications. The SLIDERBOX® family of adjustable wall boxes was designed for applications where the wall substrate thickness goes beyond the standard wallboard. With SLIDERBOX®, there’s no need to remove or relocate mounting screws to reposition the box. Most competitive designs require screw removal to reposition the box, causing extra time and labor. SLIDERBOX® also features a clean and simple exterior profile for easy cut-in or retrofit installation. Some competitors require adjustable boxes to be mounted with a stud face bracket which requires additional drywall patch and labor for retrofit installations.

Allied Moulded Products values quality in its products and customer satisfaction above all else. Over the years, Allied Moulded has invested in modern technologies and vertical integration to ensure customers receive a durable and reliable product. Most of the Allied Moulded products, including the all-new 2302-ABKSC Adjustable Fiberglass Outlet Box along with our entire SLIDERBOX® family are proudly manufactured in the USA, ensuring a quality product that meets rigorous testing and standards.

The entire SLIDERBOX® family including the all-new 2302-ABKSC is available for purchase now through Allied Moulded Products, Inc. For more information, please visit the company's website at www.alliedmoulded.com or call 1-800-722-2679 or email [email protected].

About Allied Moulded Products, Inc.

Allied Moulded Products, Inc., established in 1958, is a leader in the production of fiberglass reinforced and polycarbonate, nonmetallic electrical boxes and enclosures, for use in residential and industrial applications globally. The Bryan, Ohio-based manufacturer today is perfecting material and design formulations that result in products with increased strength, reduced weight, corrosion resistance, non-conductivity, UV resistance and ease of installation.

Sponsored by: