The earliest version of “smart lighting” offered little more than sophisticated on/off and dimming control in a market dominated by companies like Lutron, Leviton, Legrand and a few others. The lighting market has evolved to the point where if a facility upgrades its lighting to LED, adding sophisticated controls after the LED installation only generates marginal incremental energy savings. Once LEDs save 70% of the energy consumed by the lamps they replaced, the ROI on investing in controls drop off.

But that’s not the end of the story, because the benefits of the latest lighting control systems go beyond energy savings. The latest networked lighting controls can include Internet of Things (IoT) connectivity that basically puts a computer, connectivity and sensors into lights and takes them beyond on/off operation, dimming or even color tuning. Now LEDs are analogous to the smart phone in your pocket, which is much more than a phone. Today, LEDs can be data capture-and-control devices — in essence mini-computers. IoT-enabled LEDs can monitor any space and relay sensor data to highly sophisticated software programs outside the fixtures. This software analyzes the data from across the facility and provide mission-critical services to commercial, industrial and municipal facility managers. This goes beyond the value of lighting or energy efficiency and gets into business applications that improve productivity, reduce costs and/or generate sales.

Mission-critical services. In “asset tracking” applications IoT lighting can already monitor the locations of expensive equipment in hospitals, factories or warehouses. They can also monitor the utilization of conference rooms, or where shoppers are in a store. These are indoor positioning applications that lead to better utilization of commercial space and reduced space requirements, saving building owners money. In retail applications, these systems can push notifications to shoppers about products on sale and provide product education, generating more sales revenue. In a post titled “30 ways IoT lighting can solve everyday problems,” LuxReview.com provides an interesting list of applications for IoT-enabled lighting. Some of these applications may surprise you. They include streetlights equipped with sensors that detect gunshot location, parking garage fixtures that direct you to an open parking space and fixtures that guide customers through stores or visitors through hospitals, museums and other buildings with custom-colored pathways.

Platform-based lighting. The major Tier 1 lighting manufacturers are taking the smart phone metaphor for IoT lighting much farther. They want to be the platform on which these diverse software applications are built. They want to be like the iOS and Android in our phones, with scores of third parties developing the high-value applications that run on their platforms (like an App store). Only the largest lighting manufacturers can attempt this ambitious move (i.e. Acuity, Eaton, Hubbell, Phillips). And most offer proprietary systems (think Apple) only compatible with their hardware that will require distributors, contractors/installers and end-users to know each system in the market, or specialize in specific platforms.

Where the technology is going. There are two types of IoT lighting, wired and wireless. Wired IoT lighting has advantages in new construction because the new wiring can be run easily. Power over Ethernet (PoE) is an example of wired IoT lighting that uses only low-voltage computer cables for both power and data, and does not require expert installers. However, PoE requires power hubs to be installed separately to address power loss in the cable network.

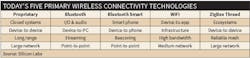

Wireless IoT solutions have significant advantages, particularly in retrofit applications. Because each light, switch or sensor in the system has a very small built-in radio, no signal wires are required. This can reduce the wiring cost, but there are many competing wireless protocols available in the market. The challenge becomes which protocol to pick.

The protocols, or technologies, include the Zigbee, Bluetooth, Thread, Wi-Fi, proprietary protocols, and many more. With so many options, it makes it challenging for specifiers and buyers as well as manufacturer and distributor salespeople to evaluate the pros and cons of each protocol, especially for the environment in which they will be installed and for the desired usage. Unfortunately, no one protocol can do everything due to their different benefits in range, data rates, mesh scalability and capabilities, and energy consumption. The chart below, developed with information published by Silicon Labs, compares the most popular wireless protocols.

The recently released Bluetooth Mesh standard was developed with lighting as a target application, but many commercial lighting manufacturers are currently developing/supporting their own proprietary or existing Zigbee mesh ecosystem until Bluetooth Mesh is field proven. Zigbee is an open standard, and with more than one hundred million devices deployed, in theory, sensors, switches, and lights can interconnect independent of fixture manufacturer. Bluetooth also has compatibility built-in, but some researchers have raised concerns that Bluetooth Mesh’s communication algorithm, combined with heavy sensor-integrated luminaires, could generate extreme heat and so much data that it overloads a network.

New wireless solutions use a single radio chip to perform multi-protocol communications that address some of the challenges with all of the protocols available. One example is to combine Zigbee with Bluetooth. The two complementary protocols enhance user experience and security. Luminaries can be commissioned easily with a mobile device via Bluetooth, while the primary network uses another secure protocol with mesh capabilities like Zigbee, Thread, or a manufacturer’s proprietary solution. Manufacturers can achieve all of this with a single radio chip that reduces size and cost, or with a faster option using pre-fabricated modules that include all of the software, antennas, and wireless know-how.

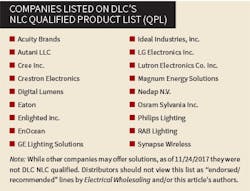

Utility rebates and the DLC NLC spec. There are interesting things happening with the Design Lights Consortium (DLC) Networked Lighting Controls (NLC) spec as well as utility rebates based on the DLC NLC spec. The DLC is a non-profit organization based in Medford, MA, that works to drive efficient lighting by defining quality and delivering tools and resources to the lighting market through open dialogue and collaboration.

It recently analyzed savings from NLC installations and found an average of a 47% savings across all buildings, but this was extremely variable by building type and from building to building in the same use or type. This DLC NLC analysis will likely be used by utility rebate programs to not only expand the number of incentive programs for NLC systems, but also to increase data and reporting requirements, in addition to meeting the technical NLC spec. See the sidebar below to see which companies are listed on DLC’s NLC Qualified Product List (QPL) as of 11/24/2017.

More than 20 utilities and other energy efficiency program sponsors now require networked control systems be on the DLC NLC QPL to qualify for their incentives. Some have simple prescriptive rebates (per luminaire), while others have performance rebates (per watt saved). For more information on lighting control rebates, check the “Utility Rebates for Networked Lighting Controls” at the Lighting Controls Association.

Challenges for distributors. There are lots of companies and technologies in this space, which can make it daunting. Other challenges include the fact that controls are a small percentage of a distributor’s business and that customer demand, at this time, is low.

The opportunity is coming, but selling this technology requires commitment. This is not a product where salespeople “accept” an order. If they do, someone has specified the job and the opportunity will devolve to a price game.

Selling infers generating demand, which requires sales training, continuous product education, marketing, recommending the right product for the solution (and hence understanding customer needs). Then there is the potential for add-on services and revenue streams. And the sale for lighting controls will frequently occur at higher levels of customer contacts than the traditional electrical distributor calls upon. The applications and benefits of the sale are more conceptual and focus on information gathering, cost reduction and revenue generation. It’s not solely a feature/benefit sale.

Leading companies in this space are educating management, their salespeople, their customers, and are investing in lighting control specialists. And some are targeting market segments to pursue and proactively generate demand.

A concern for distributors is their contractors. Some distributors are making the mistake of waiting for contractors to request these new lighting systems. Waiting equals quoting, not selling. Consider how you can arm your contractors, or preferred contractors, with tools for them to recommend — or to bring you into an opportunity as the “local expert.” Or consider how you can differentiate yourself in the market and drive business to contractors who have expertise in installing controls.

From a supplier support viewpoint, distributors should consider the pros/cons of solely understanding, selling, marketing and training on proprietary systems as well as having knowledge and access to open systems. This is an Apple vs. Google scenario. You need to support your key package lighting lines, but you also need alternatives so you can make the best recommendation and/or value engineer projects with technology that enables you to mix and match fixtures.

And don’t be afraid of FOBO (fear of a better option). These are technology platforms. They will change and this change requires you to maintain your product knowledge, but they also can provide a potential upgrade revenue stream.

A key concern for the electrical wholesaling industry is that if electrical distributors do not take the lead, lighting manufacturers will seek the channels that will generate the revenue. This could be direct sales, reps going direct as well as selling through other channels (which they are starting to do). Another evolving channel is the integration of lighting control systems into building management and security/alarm systems, which can open the door to distributors from those channels.

Controlling your IoT lighting solutions. IoT. IIoT (Industrial Internet of Things). Smart. Connected. Connectivity. Whatever term you prefer, it comes down to technology. The nature of technology is forever evolving. What exists today will change, as tomorrow’s solutions are already in development. This creates relationship, purchasing, marketing, training, sales and other challenges for manufacturers and their channels, as well as distributors and their “supply chains.”

Distributors need to decide whether they plan to be a market leader and create demand and/or add value or provide traditional distribution services and be dependent upon others to create demand. Manufacturers can try to be the next “Apple” or participate in a “Google” ecosystem.

We’re in the very early innings of a rapidly changing market. It has passed the “bleeding edge,” as the technology is proven and sales potential determined. Now the market is positioning to the cutting edge and will quickly be determined by those who want to be on the leading edge. Waiting to decide may relegate you to being on the bench.

About the Author

David Gordon

David Gordon is a 30+ year business-to-business marketing veteran. He spent the first 11 years of his career in the performance marketing industry helping clients achieve goals such as increasing sales and market share, acquiring new customers, improving customer retention, enhancing employee loyalty and building and enhancing brand awareness.

In 2001, Gordon founded Channel Marketing Group, a marketing consulting firm for electrical distributors and electrical manufacturers. He has worked with distributors in the development and implementation of their strategic plans and marketing strategies, and with manufacturers on market research, market segmentation strategies, customer specific approaches, branding initiatives and distributor portfolio strategies. He is also publisher of U.S. Lighting Trends.

He was previously V.P. of marketing and e-commerce strategies for the IMARK buying/marketing group, he developed strategies to increase manufacturer sales and market share through the group’s members and in helping members enhance their marketing efforts.

Gordon is a frequent contributor to Electrical Wholesaling and has written for Modern Distribution Management, SupplyHouse Times, TED magazine and Progressive Distributor. He has presented at NAED’s Marketing Conference, Wit's Marketing Conference, speaks at distributor and manufacturer meetings and advisory councils and has co-authored a chapter in NAW's Outlook 2009 on Private Labeling.

Check out his Electrical Trends blog by clicking here.

David Shiller

President

David Shiller is president of Lighting Solution Development (www.LightingSolD.com) a consulting firm providing engineering and business development solutions to lighting manufacturers. Contact him at [email protected] or 412-247-1843.