While the concept of vendor-managed inventory (VMI) has been around the electrical market since the 1990s, a new storeroom management system developed by Storeroom Logix (www.storeroomlogix.com), Greensboro, NC, offers an entirely new twist.

Brad McCormick, president and CEO, Electric Supply & Electric (ES&E), Greensboro, NC, says his company had tried various VMI systems over the years, but everything required more labor cost to add more VMI customers. And nothing was available that provided enough flexibility for customers who needed more than a standard VMI package. Using their electrical market expertise and experience with VMI, about five years ago McCormick’s veteran team started working on what eventually became Storeroom Logix. Sean Leahy joined Storeroom Logix in 2019 and provided additional expertise through his experience with industrial and contractor sales and integrated supply contracts, and his network of industry contacts that he developed during his 35 years in the electrical industry.

Today, Storeroom Logix is a stand-alone company that offers a customizable VMI solution that harnesses the latest thinking and technology in cloud-computing, artificial intelligence, automated equipment mobile technology and sophisticated scheduling software to provide distributors and their customers with a low cost, simple-to-use solution that can slash a customer’s inventory costs by 25% to 40%. In other words, the “storeroom of the future” is available today. And due to technology, it’s less expensive than doing it the old-fashioned way.

ES&E says on its website, “Every customer is different and requires customized inventory solutions. ES&E Inventory Solutions partners with Storeroom Logix so a solution can be mixed and matched to accommodate any size storeroom. And ES&E is not alone. Sean Leahy says in addition to a number of electrical distributors moving to their platform, Storeroom Logix is working with industrial, safety, chemical, adhesive and automotive distributors as well.

Andrea Mainiero, VP of development and architect of the Storeroom Logix solution, says Storeroom Logix provides distributors and their customers with extensive inventory forecasting recommendations that factor in customer ordering history and distributor stock levels. The Storeroom Logix team has found that oftentimes customers may have way more inventory on hand than they need just to be sure they don’t have a stock-out. Utilizing Storeroom Logix SRX software analytics, a distributor can help a customer drill down into their order patterns and history product-by-product to determine the best refill rates.

She adds that a customer’s inventory is often very static, sometimes for years at a time. A customer may have had a project four years ago that required 30 of a certain item. There’s a chance, she says, that there's 30 products in that bin today, even if they only use one or two of them a year. “Why should a customer stock 30 days of inventory when they have a distributor that delivers to them five days a week, and who has several hundred customers buying that exact same part number?,” she says. “They may have five or six hundred on the shelf.

When determining economic ordering quantity, Storeroom Logix factors in the cost of a product and the typical ordering patterns for it. For instance, it might not make sense to order wire connectors five times a week because they are so inexpensive, and instead order them perhaps twice a month. In contrast, with expensive automation components, it makes more sense for them to replenish those as necessary because of the value of the item and the possibility of getting stuck with dead stock.

“We also look at what type of customer they are,” says Mainiero. “Are they a panel shop or a contractor? Are they a maintenance facility? Because all three of those have different buying habits. Then we also look at the distributor's inventory in stock.

“We also calculate average replenishment time for the manufacturer. It may be that a manufacturer’s lead time is starting to go up. If so, our software will automatically recommend higher min-max levels, if the customer has enabled that feature. It's one of the biggest customer benefits and value-adds,” she says.

The Storeroom Logix SRX software also takes standard packaging quantity into account. One example is limiting a customer’s orders of wire connectors to full packages of 50, so a customer couldn't just order 15 wire connectors.

The software also adapts to the sophistication of the customer. If the customer enables the feature, Storeroom Logix can turn a VMI order into an e-commerce order because their software is tied in directly into the distributor's ERP system. But if a customer is more comfortable being notified about potential reorder points through email alerts and spreadsheets with product data, they can do that, too.

Leahy says one of the other big sales features with Storeroom Logix is how easy it is to set up the catalog of products in the storeroom agreement. They use a simple interface or API to add cut sheets, images and any other material for a product’s listing. “Once we set up the catalog, it’s done,” says Leahy. “If the distributor adds material or manufacturer adds a certain part number and that automatically updates the distributor system, it will automatically update in the Storeroom Logix system as well.”

STOREROOM LOGIX VMI PACKAGE FEATURES

While the SRX Software drives the VMI solution, Storeroom Logix provides an equipment package that provides a turnkey VMI solution for distributors to offer their customers.

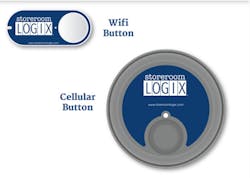

Re-order buttons. Certain products may have spikes in demand before a distributor’s VMI person gets to the facility to check stock levels. When they need more products, customers simply push a cellular or WiFi-enabled smart button to notify the distributor the product needs to be reordered.

Picture an electrician walking over to a bin and removing the last part, they simply push the button and a replenishment order is automatically sent to the distributors ERP system. No phone calls, emails, or upset customer due to a stock out. .

Mainiero says the WiFi-enabled smart buttons work right out of the box and that it’s simple to link products to bin locations. All users need to do is use the smartphone app to scan the bar code item on the back of the button and the bar code on the part number of the item.

Smart shelves and smart bins. These storage devices are programmed with weights of a product, and are accurate to the weight of a credit card. The system automatically adjusts the counts when the weight of products changes, and automatically reorders when necessary.

Smart lockers. For high-value product items that need to be secure, the Storeroom Logix Smart Lockers are similar to the industrial vending machines that some other distributors offer, except for one importance difference – the Storeroom Logix lockers are connected to the distributors ERP system and to the SRX software so the distributor can remotely monitor bin quantities and reorder points. When a product dispenses, the order is automatically transmitted to the distributor ERP through SRX. These lockers can be programmed so that an employee needs to use their ID card to open them. Customers can provide and restrict access.

RFID towers. Similar in concept to the restricted access functions of the Smart Locker, the RFID towers restrict access to certain areas only to employees who display their employee ID or security fob. “They go into the storeroom and pick what part they need,” explains Leahy. “The software identifies who took the part, when they took it and how many they took.” “Our system also utilizes allocation codes to track where products are being used.”

Crib crawl app. Identifying, inspecting and counting SKUs in a customer’s tool crib or storeroom can be quite time consuming and prone to errors. Storeroom Logix has developed a crib crawl app so customers can use their smartphones to scan the bar code on a product to get information like part number or bin location. Distributors have reported 80% time savings using the SRX Crib Crawl app.

Life cycle status. For those products in a customer’s storeroom that can become obsolete, the Storeroom Logix system can be programmed to show lifecycle status through a green dot (up-to-date); yellow dot (nearing end of life); or red dot (needs replacement) color configuration.

Job costing. The software can also help customers see where products are used so that they can apply the costs by project or internal department.

Sales and marketing support. Storeroom Logix provides distributors with a complete suite of marketing and sales support including customizable brochures, PowerPoint presentations, videos, proposal builders and tools to help distributors make more profit when providing VMI as a service.

Summary. Leahy and McCormick say one of the biggest advantages of Storeroom Logix is that we evolved out of an electrical distributor at the perfect time. "We understand the pain and problems distributors had with VMI in the past and we were able to develop a cloud-based solution that takes us into the future," says Leahy. “We are obsessed with providing distributors with a low-cost way to improve their service offering, make more money doing it, and competing in a way they couldn’t before."

He says that one of the advantages of the Storeroom Logix system is that once customers see how they can control their inventory and reduce costs, they typically can’t stop using it. “It’s very sticky,” he says, “It’s hard for a customer to leave a distributor when they are resolving their problems. Now more than ever you must sell service and solutions, not just parts and price,” says Leahy. “When you can provide this level of VMI solution, it’s a competitive advantage.”

About the Author

Jim Lucy

Editor-in-Chief of Electrical Wholesaling and Electrical Marketing

Jim Lucy has been wandering through the electrical market for more than 40 years, most of the time as an editor for Electrical Wholesaling and Electrical Marketing newsletter, and as a contributing writer for EC&M magazine During that time he and the editorial team for the publications have won numerous national awards for their coverage of the electrical business. He showed an early interest in electricity, when as a youth he had an idea for a hot dog cooker. Unfortunately, the first crude prototype malfunctioned and the arc nearly blew him out of his parents' basement.

Before becoming an editor for Electrical Wholesaling and Electrical Marketing, he earned a BA degree in journalism and a MA in communications from Glassboro State College, Glassboro, NJ., which is formerly best known as the site of the 1967 summit meeting between President Lyndon Johnson and Russian Premier Aleksei Nikolayevich Kosygin, and now best known as the New Jersey state college that changed its name in 1992 to Rowan University because of a generous $100 million donation by N.J. zillionaire industrialist Henry Rowan. Jim is a Brooklyn-born Jersey Guy happily transplanted with his wife and three sons in the fertile plains of Kansas for the past 30 years.