Italian economist Vilfredo Pareto observed in 1906 that 80% of the land in Italy was owned by 20% of the population. Then business management thinker Joseph Juran developed the 80/20 principle and named it after Pareto by observing that 20% of the pea pods in his garden yielded 80% of the peas.

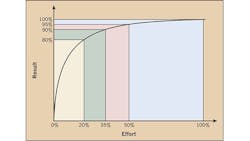

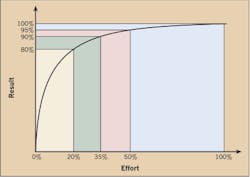

Pareto would suggest that we apply different technologies and different methods to the different SKU segments that generate 80% of the business. In other words, apply multiple technologies to optimize the efficiency within the different “bandwidths” of the Pareto Curve (see chart).

What does this have to do with your distribution center design? If you are using a single-method picking strategy in your warehouse for both your fast- and slow-moving products, you may be missing out on some huge opportunities for efficiency productivity improvement and lower costs. You can leverage the different bandwidths in this Pareto Curve by applying some smart design, methods, and technology.

Some distribution centers may be just outdated and operate within the confines of a lot of manual solutions (their own single technology systems). Often, that technology is people — an army of people (“walkers”) trudging through the distribution center with carts and forklifts, armed with that one technology. I’ve said it many times in my articles and presentations: 70% of a picker’s time is spent walking and just 30% of the time is spent actually picking. Out of an eight-hour day, that’s less than 2-1/2 hours of actual picking. Not very efficient.

Picking Strategies vs. the Pareto Curve

Utilizing Pareto, you can ensure your pickers don’t have to pass up to 80% of the SKUs to find the ones they want. To do this, you can employ a variety of methods and technologies to reduce walk time:

- High-velocity pick zones

- Narrow aisle storage and picking zones

- Carousels (bringing product to the picker)

- Zone picking

- Batch and/or wave picking

Each of these options reduces the percentage of time walking, and conversely increases actual productive picking time. The principle here is really quite simple — concentrate the fast-moving, frequently-touched SKUs in a single area, maybe even their own picking zone. Think of it like the “penthouse residents” versus the “basement dwellers” (those slower-moving SKUs that often reside in the same building). If you’ve ever done a “Pareto Analysis” on the inventory in your warehouse you have found relatively few SKUs account for a high percentage of picks (order hits). I often find that for typical distributors with 10,000 to 15,000 SKUs, 20% to 50% of the hits are represented by just 500 to 1,700 SKUs — the A-items. The numbers don’t always conform exactly to Paretto’s 80/20 rule, but you get the point.

Summary. Leveraging this imbalance is an opportunity to force tremendous change and productivity benefits as well as improvement in your operational cost metrics. You may need multiple methods, some new technology and possibly some updated materials storage media, materials handling and conveyance equipment. You also may need different work processes in place to address those different “bandwidths” all along that Pareto Curve. This could include flow-racking, narrow aisle storage, conveyors, etc.

So, if you are already familiar with the Pareto Curve, say hello to your old friend. If not, it’s time to meet him.

MCA Associates, Derby, Conn., a management consulting firm since 1986, works with distributors and manufacturers to help them implement continuous improvement solutions focused on business processes, inventory and supply chain management, distribution center/warehouse design and productivity improvement, sales development and revenue generation, information systems and technology, and organizational assessment and development including family-business succession planning. For more information, contact Howard Coleman, the company’s president at 203-732-0603 [email protected].

About the Author

Howard Coleman

The author is the principal of MCA Associates, Derby, Conn., a management consulting firm founded in 1986. MCA implements continuous improvement solutions focused on business process re-engineering, inventory and supply chain management, sales development and revenue generation, information systems and technology, organizational assessment and development, and succession planning. You can contact him by phone at (203) 732-0603 or by e-mail at [email protected].