As an engineer and former officer in the U.S. Navy, Greg Puschnigg looks at things with a different eye. While serving the U.S. Navy as a shipboard engineer, he monitored and maintained a vessel’s electrical, mechanical, hydraulic and navigational systems, often in the middle of the ocean hundreds of miles from the nearest port. Managing a ship’s critical systems translates really well to managing a building’s operations. And it also may have more than a little bit to do with the development of the IoT-enabled plug-load controls that his company, BOSS Controls, Pittsburgh, sells.

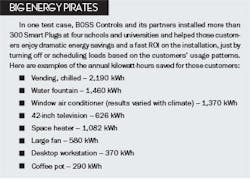

Puschnigg, the CEO of BOSS Controls, is going after the 30% of electrical demand typically accounted for by plug-load devices in a building – in particular the estimated 5 million buildings in the United States under 100,000 sq ft., and the 80% of them that have no consolidated energy management control system. His company’s primary mission is producing bottom-line savings on the monthly electrical bills of K-12 schools, universities, municipals and other government facilities, hospitals, offices and other commercial properties by trimming electrical power demand accounted for by plug-in loads like vending machines, water fountains, water coolers, computers, space heaters, coffee pots, televisions and LCD and plasma monitors. But Greg Puschnigg and his merry band at his Pittsburgh headquarters in a renovated bakery are cooking up something even bigger.

Harnessing IoT

The company has developed its Atmospheres software to collect data from the BOSS Smart Plugs to help school administrators, CFOs, building owners, energy managers and public officials not only provide energy savings to the building owner but use the data to provide other operational savings such as predictive maintenance and other smart buildings metrics. In addition, the ability to mass control these devices produces huge value for local utilities interested in shaving electrical demand from commercial customers, particularly during critical peak demand periods so they don’t have to generate as much power. BOSS Smart Plugs come with a one-year free subscription to the company’s Atmospheres energy management app. After the first year access to the Atmospheres software costs one dollar per device per year.

Puschnigg looks at the ability to mass control the smart plugs to turn off devices during peak demand periods as a “virtual power plant” that users can utilize to produce savings and lessen the load on the local utility. The Smart Plugs can also help building owners and other energy managers meet some of the regulations now on the books like the California Energy Commission (CEC) Title 20 and Title 24 plug load requirements and California’s SB-350 Clean Energy and Pollution Reduction law. “Obviously, our costs being virtual capacity are far less than that physical plant operation,” he says. “That’s where that deregulation of the markets is really changing things, the codes are changing things, forcing electrical outlets to have some sort of controls. We do demand response but we are aggregating it from the inside out. It’s very different. Our customer is the building owner and operator and we provide a service back to the utility, not the other way around.”

The BOSS Controls Smart Plugs are controlled remotely, either individually or in user-defined group over customers’ existing WiFi networks. They typically are set up as a separate SSID (wireless network) on the building’s existing commercial routers and don’t interfere with other WiFi networks on that equipment. Competing products currently rely on hard-wired networks or the Zigbee wireless protocol. BOSS Controls currently programs the devices before shipment, but the actual installation takes as little as three minutes.

Another link back to Puschnigg’s Navy days is his insistence that BOSS Smart Plugs are super-easy for users to understand and use. “I came from the Navy where all instructions are written to 8th-grade level of education,” he says. “Lots of diagrams and photos, because that’s the average level of reading. That made a lot of sense to me. Everything we do is focused on making it ‘sailor proof.’ Eighty percent of what we do it is very simple functionality — on/off, etc. Our control is intuitive in how it works.”

Where the Rubber Meets the Road

The folks at BOSS Controls have a blast finding unusual applications for their controls. Puschnigg talked with executives at BestBuy and found that they wanted to get away from the time-consuming and expensive task of powering up/powering down all of their televisions and electronic devices each day, which typically involves having an employee individually control each device with a remote. And Dan Brailer, the company’s COO and the former V.P. of investor relations for WESCO Distribution, says the company has talked with building managers of stadiums and found applications for remotely managing the electrical loads in the suites.

She says C-Leveled helped BOSS develop a “full-circle digital marketing campaign” that targets contacts at “Tier 1 and Tier 2” schools on the K-12 level that already had experience with energy retrofits with an ESCO or a trade ally like an ESN to revamp LED lighting, for example. “We built a list of K-12 Tier 1 schools and then looked at who would be the best contact within that school to market to, such as superintendents and business managers,” she says. “At the higher education level it tends to be CFOs and energy managers.”

Fisher says a key step in getting a customer to buy into BOSS is to do a test installation at their facility with about 20 to 30 controls and spend several weeks measuring the facility’s energy demands. “Then we start controlling stuff, turning things on and off when not needed,” says Fisher. “The beauty of it is that because we do real-time real measurement it’s not spreadsheet magic. It’s the real thing, and it has a lot of credibility with these facilities guys who often are grizzled late-50s veterans who have heard it all.”

One challenge that occasionally surfaces is getting a customer’s IT department to buy in because they are often protective of their turf and may be concerned about BOSS’ use of WiFi as a communications network, “They don’t want outside entities invading their networks,” he says. “That can be a challenge to get them onboard.”

Fisher adds that the concept of virtual power may not always be a selling point with facilities personnel, but that it hits home with utilities. “They love it because they can build to average load rather than peak load. That saves them billions. Rather than resisting, they see they don’t have to build that big new power plant. As real time pricing starts to happen, this is going to be a key piece of that.”

Channels of Distribution

Electrical industry consultant Paul Eitmant, who serves as BOSS Controls’ V.P. of channel development, says that while the concept behind the BOSS Control devices and the Atmospheres software is pretty easy to grasp for any reasonably technically inclined person, the electrical distributors, system integrators and other companies selling and installing them in the field will need a working knowledge of the IT environment and wireless networking, and the ability to assist customers with applicable utility rebates for the devices. He believes many of these companies will function as hybrid distributors that cross over between the electrical, IT and energy fields.

One company that signed on early with BOSS Controls is N3 Technologies (N3TI), Newport Beach, Calif., an IT specialist that does network configuration for BOSS Controls, Avaya, Cisco, Dell, Microsoft and other tech companies. Jeff Nordstom, the company’s CEO, says California is a good market for BOSS Controls because of all the state energy regulations and the fact that electric utilities are open to new ideas to cut energy demand because of the high cost there of new plant construction. He recently installed 60 Smart Plugs in the College of the Canyons community college and said the administrators there were particularly surprised by how much energy water fountains were using in off-hours. “They were pulling 240W. Those refrigeration units run all weekend and on Fridays (when classes are not in session) so it’s a huge opportunity to save energy.

“It is hard to explain it on the front end but once they see it, it becomes very simple. In the school itself 3,000 computers are running. Just turning off those computers for the weekend is an opportunity for them to save money. We installed the 60 units in about three hours, and could have done it in two hours if we were little more efficient.”

BOSS Controls has attracted a number of private investors for capital support. Puschnigg won’t rule out a public offering or potential acquisition of the business, but he is intent on guiding BOSS Controls to make the most of the enormous market opportunity he sees as more electrical devices and systems become IoT-enabled. Along with the company’s current line of Smart Plugs, he wants to eventually blend the BOSS Controls technology into wiring devices, thermostats, switches and other devices.

“Everything that has been installed over the last 100 years will be changed out,” he says. “At the same time, new construction is going to occur. The cost of energy is the third or fourth most expensive line item. If you can eliminate 30% of that, it’s huge. It’s a fun time. BOSS Controls isn’t just a one-time product sale. It’s the services that go with it, and software, and analytics that will come out as we have products that act as a system.”

About the Author

Jim Lucy

Editor-in-Chief of Electrical Wholesaling and Electrical Marketing

Jim Lucy has been wandering through the electrical market for more than 40 years, most of the time as an editor for Electrical Wholesaling and Electrical Marketing newsletter, and as a contributing writer for EC&M magazine During that time he and the editorial team for the publications have won numerous national awards for their coverage of the electrical business. He showed an early interest in electricity, when as a youth he had an idea for a hot dog cooker. Unfortunately, the first crude prototype malfunctioned and the arc nearly blew him out of his parents' basement.

Before becoming an editor for Electrical Wholesaling and Electrical Marketing, he earned a BA degree in journalism and a MA in communications from Glassboro State College, Glassboro, NJ., which is formerly best known as the site of the 1967 summit meeting between President Lyndon Johnson and Russian Premier Aleksei Nikolayevich Kosygin, and now best known as the New Jersey state college that changed its name in 1992 to Rowan University because of a generous $100 million donation by N.J. zillionaire industrialist Henry Rowan. Jim is a Brooklyn-born Jersey Guy happily transplanted with his wife and three sons in the fertile plains of Kansas for the past 30 years.